Reliable Strapping Manufacturer

Pro Strapping Solution, top strapping supplier with 25+ years experience. We engaged in load and cargo securing since 1999 and has exported to 30+ countries.

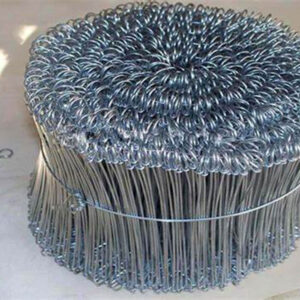

As an ISO 9001 and 140001, CE, RoHs, SGS and AAR certified factory. We specialize in manufacturing high quality strapping, strapping accesories and tools , including plastic strapping, cord strapping, steel strapping, wire buckle, strapping tensioner etc.

We can custom strapping solution for a multitude of applications and industries. With pofessional R&D team and competitive prices, looking forward to cooperate with you.

Jastar Hot-Sale Paper Boxes

Types of Paper Boxes We Made

Paper Box for Food

Paper food boxes and take out containers – durable heavy gauge made from sustainable plant resources.

Get a free quote

Corrugated Box/Corrugated Paper Box

Corrugated paperboard is stronger variant for bulk items.

Get a free quote

Get Your Custom Paper Box

Jastar is a trusted paper box manufacturer with years of experience in creating high-quality packaging solutions for various industries. It specializes in manufacturing high-quality custom paper boxes to cover various needs of customers. Here are your custom selections:

Strapping Manufacturing Process

-

Material Selection and Preparation: plastic strapping/metal strapping

-

Forming and Shaping: Stretch and emboss the plastic strip (Plastic Strapping) or Heat treat and coil the metal strips(Metal Strapping).

-

Surface Treatment and Coating: Apply coatings like UV protection, anti-corrosion, and anti-slip to enhance performance.

-

Customization and Finishing: Add custom colors, print logos/marks, and cut to specified lengths.

-

Quality Control and Testing: Conduct tensile, elongation, and durability tests to ensure high standards.

-

Packaging and Distribution: Spool, label, and package the strapping for shipment.

Strapping Benefits

- Safety and Stability(Secure Fastening): Keeps goods tightly secured, preventing damage and movement during transit.

- Versatility(Wide Application Range): Suitable for various products and industries, adaptable for different sizes and weights.

- Flexibility(Adaptable Solutions): Can be customized to fit different shapes and sizes, offering flexible packaging solutions.

- Eco-Friendly(Sustainable Materials): Available in recyclable materials, reducing environmental impact and supporting sustainability.

Packaging Product Application

Pro Strapping Solution is the best protection for large, bulky and heavy cargo when the goods are in the container shipping or road transportation. Your best choice of strapping factory! Custom sreapping solution for all industries.

Strapping for Food and Beverage

Securing cases of bottled beverages, canned goods, and other food products for safe distribution.

Strap for Manufacturing

Securing cases of bottled beverages, canned goods, and other food products for safe distribution.

Banding for Logistics and Shipping

Securing goods on pallets, stabilizing cargo in containers, and bundling packages for safe transport.

Strapping for Construction

Securing bundles of building materials like bricks, tiles, and lumber, and stabilizing pipes and rebar.

Banding in Medical Industry

Securing medical equipment, devices, and pharmaceutical product for safe and hygienic transport.

Banding in Agriculture

Binding bales of hay, straw, and securing crates of fruits and vegetables for transport.

Strapping for Retail and Distribution

Packaging and securing consumer goods, electronics, and clothing for distribution to retail stores and customers.

Strapping for Automotive

Bundling automotive parts and components, securing tires, and stabilizing shipments of assembled vehicles.

Why Choose Us as Strapping Solution and Supplier

Advanced Production Line Equipment

With more than 25 years of experience in product manufacturing. First-class strapping proddution line creates high-quality products for you. 20+ automatic machines fasten production efficiency

Low Price and High Quality

One stop service can reduce costs and improve quality standards. Arrange from design, material, processing, delivery time, quality inspection and transportation. Reduce any additional costs throughout the process.

Fast and Convenient Delivery

Fast production, early delivery, reliable logistics, can provide door-to-door service. Various transportation modes meet different countries.

4,000 Square Meters Factory

The warehouse storage area reaches more than 4,000 square meters. We have excellent R&D team, strict Q&C team and after sale team。

What Our Other Customers Say About Us

After-Sales Support

1. Technical Assistance

- Expert Support: Our technicians offer guidance and troubleshooting.

- Installation and Setup: Support for proper installation and setup of equipment.

2. Maintenance and Repairs

- Preventive Maintenance: Routine maintenance to prevent issues.

- Repair Services: Prompt repairs to minimize downtime.

3. Spare Parts and Accessories

- Parts Availability: Stock of essential spare parts and accessories.

- Easy Ordering: Convenient ordering through customer service or online.

4. Training and Consultation

- Training: Sessions for staff on equipment operation and maintenance.

- Consultation: Expert advice to optimize strapping processes.

5. Customer Support

- Responsive Service: Prompt response to inquiries and concerns.

- Feedback and Improvement: Continuously improving based on customer feedback.

Our Partner

Industrial Strapping FAQs

- Use the Right Tool: Always use a cutter specifically designed for steel strapping to ensure a clean and safe cut.

- Inspect the Cutter: Regularly inspect the cutter for sharpness and proper function. Replace worn or damaged blades as needed.

- Avoid Over-Tensioned Straps: Do not cut strapping that is under excessive tension, as it can snap back and cause injury.

- Keep a Firm Grip: Maintain a firm grip on the cutter handles to control the cutting process and prevent accidents.

Yes, iwe can custom strapping for you, including width, thickness, length, color, and printing with logos or identification marks.

The types of strapping materials available include:

- Polypropylene (PP) Strapping: Lightweight and cost-effective, suitable for light to medium-duty applications.

- Polyester (PET) Strapping: Stronger and more durable than polypropylene, ideal for heavy-duty applications and maintaining tension over time.

- Steel Strapping: Extremely strong and rigid, perfect for securing heavy loads and materials with sharp edges.

- Eco-Friendly Strapping: Made from recyclable or biodegradable materials, reducing environmental impact and supporting sustainability initiatives.

-

Composite Strapping:Composite strapping offers high tensile strength similar to steel, combined with the flexibility and safety of polyester. It is resistant to weather, UV light, and chemicals, making it ideal for securing heavy and bulky loads.

-

Cord Strapping:Cord strapping is made from bonded polyester fibers, providing strength and excellent shock absorption. It is lightweight, safe to handle, and does not damage surfaces, making it suitable for various industrial applications.

-

Woven Lashing:Woven lashing is made from high-strength polyester yarns, providing superior tension and abrasion resistance. It is used with buckles and tensioners to secure large and heavy cargo in logistics and transportation.

Choosing the right strapping material for your application involves evaluating several critical factors:

-

Product Size and Weight:

- Light to Medium Loads: Polypropylene (PP) or cord strapping.

- Heavy Loads: Polyester (PET) or steel strapping.

-

Load Value and Dimensions:

- Consider the value and dimensions of the load to ensure the strapping can securely handle the weight and size without damaging the goods.

-

Mode of Transportation and Shipping Requirements:

- Road, Rail, Sea, or Air: Different transportation modes may require specific strapping materials for optimal performance and security.

-

Easily Applied and Can Be Re-Tensioned:

- Ease of Application: Polyester and cord strapping are easier to handle and apply.

- Re-Tensioning: Some strapping materials allow for re-tensioning if the load settles or shifts.

-

Environmental Conditions and Storage Needs:

- Outdoor Use: Materials like polyester or composite strapping are resistant to UV light and weather.

- Chemical Exposure: Choose chemically resistant materials such as composite or polyester strapping.

-

Application Method and Safety Hazards:

- Safety Concerns: Polyester and cord strapping are safer to handle than steel, which can cause cuts and injuries.

- Application Method: Consider the tools and equipment required for applying the strapping.

-

Strap Gauge and Width Requirements:

- Ensure the selected strapping material meets the gauge and width requirements for your specific load and application.

-

Annual Strap and Seal Costs:

- Evaluate the cost-effectiveness of the strapping material by considering annual usage and the cost of straps and seals.

By evaluating these factors—product size and weight, load value and dimensions, mode of transportation, ease of application, environmental conditions, application method, strap gauge and width requirements, and annual costs—you can select the most appropriate strapping material for your specific packaging and transportation needs.

Manual tools are hand-operated and suited for low volume; automated tools are efficient and ideal for high volume.