Bale Ties

Pro Strapping is leading bale ties manufacturer. We are your trusted partner for high-quality bale ties, including single and double loop bale ties, auto and manual tie baler, serving industry-leading recyclers,packagers, grocery stores, retailers and municipalities.

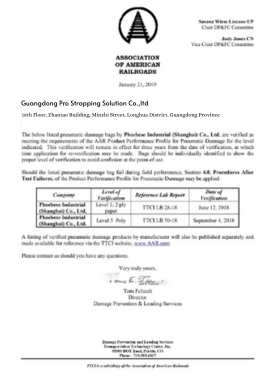

We have rich experience in manufacturing bale ties with related certification. Each batch of galvanized baling wire and annealed wire is rigorously tested for reliability and backed by our 100% guarantee. Contact Us Now.

Send Inquiry